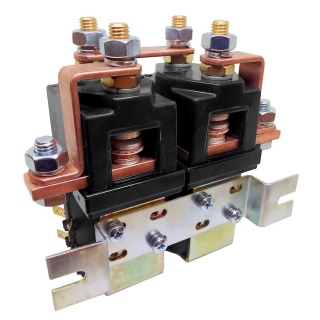

Albright SW202-136 double-acting 24VDC 250 Amps strapped pair contactor with magnetic blowouts for hydraulic motor-reversing, intermittent coil.

- Paired and linked 24 Volts DC single-pole, double-throw (SPDT) switch solenoids.

- The SW202 series of contactors has been designed for direct current loads, particularly motors as used on small electric vehicles such as industrial trucks, warehouse forklifts, airport tractors, etc.

- The contactors are compact in size and are fully serviceable, with a range of spare parts available.

- Repair contact kit part number: 2155-136.

- Auxiliary switch kit part number: 2155-202 (1 kit does 1 x coil).

- Fitted with magnetic blowouts as standard.

- With reversed top covers.

- This unit is supplied without a mounting bracket.

Dimensions

- Height including terminals and coil base cap: 152mm.

- Cap width: 2 x 48mm.

About The Intermittent SW202-136 Reversing Contactors

Intermittent contactors by design are predominantly used for hydraulic functions on vehicles, they switch quicker than continuous solenoids and are not recommended for prolonged contact periods.

The SW202 is a configuration of two 'Single Pole, Double Throw' type contactors on a common bracket for motor reversing. The SW202 features single-pole, double-breaking main contacts with Silver-alloy tips, which are weld resistant, hardwearing and have excellent conductivity.

The SW202 main contact circuit, designed for motor reversing, is such that it has a built-in failsafe, so that if both coils are energised simultaneously the contact arrangement is open circuits.

The SW202 has M10 stud main terminals and 6.3mm spade coil connections. The mounting of the solenoid can be horizontal or vertical, when vertical the M10 contact studs should point upwards.

| Interrupted Current: The opening and closing on load with frequent switching (resulting in increased contact resistance). |

| Uninterrupted Current: No or infrequent load switching requirements (maintains a lower contact resistance). |

Magnetic Blowouts

These contactors are fitted with magnetic blowouts across contact gaps as standard. These enable high currents to be ruptured very quickly so that arcing time is reduced to a minimum. Fitting of blowouts can make the contacts polarity sensitive and the positive markings on the top cover of the contactor must be observed.

Specifications

| Device Type | Paired SPDT |

| Voltage | 24V D.C. |

| Coil Type | Intermittent |

| Amps | 250A |

| Coil Resistance (Ohms) | 15 |

| Pull-In Voltage (V) | 12.0 Maximum |

| Drop Out Voltage (V) | 6.0 Maximum |

| Coil Power Dissipation (W) | 38.40 |

| Typical Pull-In Time | 40ms |

Typical Voltage Drop Per Pole

Across New Contacts At 100A | NO: 40mV

NC: 40mV |

| Operating Ambient Temperature | -40 to +60℃ (guide) |

| Guideline Weight | 3.35kg |

| Application | Uninterrupted |

| Thermal Current Rating | 250A |

| Intermittent Current Rating: |

| 30% Duty | 450A |

| 40% Duty | 390A |

| 50% Duty | 360A |

| 60% Duty | 320A |

| 70% Duty | 300A |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)